PRODUCTION MANUFACTURING PROCESS AND TECHNOLOGIES USED

The trading mechanism and production process of Hanwa Steel Centre (M) Sdn Bhd principal activities are as follows:

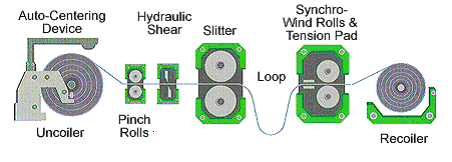

Slitting

Slitting is used to cut a bigger width coil into a number of narrower coils, called “mults” with repetitive accuracy at high speed. Generally, coil slitting lines are available in single loop and double loop configurations, depending on the grade of material and thickness to be processed.

Our Group utilises slitting machinery with high running accuracy of knife arbors, accurate knife clearance setting and well maintained knife cutting edge conditions in order to minimise burr strip edges. The table below shows the slitting process flow chart:

| Stage | Process |

| 1 | The slitting process begins with the uncoiling of the large mother steel coils. During the uncoiling procedure, the steel coils are aligned using an auto-centering device. |

| 2 | The aligned steel coils passes through the pinch rolls to be flattened. If necessary, the coils are then cut into pre-determined lengths by a hydraulic shear. |

| 3 | Subsequently, the coils are fed into a slitter to slit the coils into strips of specific widths. |

| 4 | The strips are then relayed through synchro-wind rolls which provide tension for recoiling before the finished product is discharged. |

The critical determinants in consistent slitting of quality with repetitiveness even after many years of continuous operation are:

- parallelism and arbour roundness; and

- robustness of arbour or arbour design to withstand load during slitting. Both arbours are supported on tapered roller bearings and sleeves.

To enhance productivity and quality, pit mounted coil cars are made available at the uncoiler and recoiler ends. This is to facilitate quick input and discharge of output coils. Functionless tensioning device like belt bridle tensioning system has been installed. Compared to the conventional friction pad tensioning system, the belt bridle provides for evenly tensioned mults, scratch-free slitted coils, even on shining or paint coated or galvanised surfaces. Burr strip edges is minimal due to high running accuracy of knife arbours, accurate knife clearance setting and well maintained knife cutting edge conditions.

Cut-to-length/Shearing

Cut-to-length/shearing refer to the cutting of steel coils into steel sheets and/or plates of pre-determined lengths. The shearing machines use numerical length control to facilitate the production of accurate sheet length and straight-line cuts. The table below illustrates the cut-to-length process flow:

| Stage | Process |

| 1 | This process begins with the uncoiling of the large mother steel coils. |

| 2 | Once uncoiled, the steel coils are loaded into the finish leveller to make the coils as flat as possible before they are fed into a hydraulic shear to be cut into precise lengths according to customers’ requirements. |

| 3 | The resulting steel sheets and/or plates are automatically stacked by a stacking unit which controls the number of sheets per stack. Subsequently, the stack is delivered to a pack conveyor for packing. Any unused coils can be recoiled for future use. |

Cut-to-length/shearing performs a variety of functions including cut sheet levelling, edge trim, cut-to-length and stacksheets. Hanwa Steel Centre (M) Sdn Bhd offers two (2) cut-to-length types, namely start stop line and rotary shear line.

In start stop line, feeding of material will be stopped for cutting when the required length is reached. In the case of rotary shear line, feeding is continuous (non-stop) while the required length is cut, thus enabling high volume production.

Sheet length precision and repeatability in accuracy is not only due to the precision built machine, but also in the quality and reliability of the numerical length control in order to achieve the precision flatness, multiple back-up rolls acting on the work rolls allow flexibility in work roll adjustment. Different work roll configurations are possible to correct various sheet shape defects.

Edge trimming is incorporated in the rotary shear line. This allows a slitting function to be carried out at cut-to-length without going through a slitting line. In order to handle the high output, the rotary shear line is equipped with multiple stacking arrangements. This enables the line to continue processing, while completed stocks are being discharged.